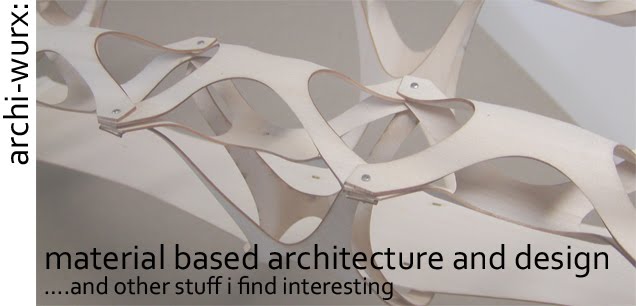

some preliminary components for my art of detailing project. these are some MDF pieces matt and I cut out wednesday morning. The final round I may cut out of foam and then cast them in aluminum....we'll see

Saturday, November 28, 2009

old power hacksaw

found an old power hacksaw, cleaned it up a little bit and replaced the base

maybe not worth the time- but it was fun working on it.

I think it could be a cool addition to my shop once it is all finished

Monday, November 23, 2009

Sunday, November 22, 2009

Wednesday, November 18, 2009

more progress on the panel

here are some pictures of our panel that frankie took a few minutes ago. I had to leave a little early tonight to watch ava so I am missing all the fun and it is killing me! me and ava almost went into the studio to work, but she would definitely have tried to eat the model pieces. so thanks to frankie and matt for hanging around and pushing on without me.

we still have to tweak everything, but this was definitely a big step.

Friday, November 13, 2009

LED's added- almost done

here are some shots of the LED lights installed. we used a thin strip of lights embedded in the bottom of the acrylic panel. can't wait to see this completed. next we are going to install the mechanics that allow the glazing to be operable. most of the parts are already milled....the end of this project is in sight!

Thursday, November 12, 2009

finally putting some pieces together!

here are some lower quality images I took with my phone....I will post some better pics soon. It's great to see this thing finally coming together!

Monday, November 9, 2009

Sunday, November 8, 2009

more cnc action- cutting with all 3-axis!

This is my first attempt at cnc milling an object on multiple sides

I had to make a jig that would hold the work piece exactly where I needed it to be after I flipped it.

The last picture shows a finish option we tried on the test piece. It is milled aluminum that is sandblasted and then polished- I really like the look of it.

After a rough Saturday of learning to operate and write code for the cnc machine things went very smooth today. Each clip took about 56 minutes to cut- each side is about 25 minutes and the original profile cutout took about 6 minutes.

Four more to go!

Friday, November 6, 2009

cutting some small parts

matt and I finally got rolling on cutting some parts on the cnc- we cut about (70) small parts out of aluminum this evening working towards a model that should look like this.

really starting to see the potentials of the cnc machine

tomorrow we will try to mill a two sided object hope it goes well!

Thursday, November 5, 2009

connector design

The new connector design - going to try to cnc this thing out of aluminum either tomorrow or this weekend. Hope it goes well....stay tuned

Wednesday, November 4, 2009

the cnc machine is online and cutting!

some test runs in r-board

the setup - tweaking some of the bugs in frankie's studio

i think we have most of the glitches worked out

its running really well now!

cutting some 1/8" aluminum with a 1/16" endmill - making some very small parts

can't wait to keep cutting- and so glad the setup went so smoothly

Monday, November 2, 2009

some very cool shop pics

these are some pictures that a friend of mine (mark hawkins) took of another friend's (andy wegner) shop. andy recently started a stainless steel fabrication business making mostly metal pans, so a lot of shearing, bending and tig welding. i really liked these pictures- there are some more good shots on andy's blog. mark is always able to capture some amazing photos- he has a great blog of his work too.

grasshopper: spaceframe

this is created in rhino with the grasshopper plugin

this is a spaceframe I am working on for a project at work. it is totally parametric- each individual ring, the number of segments of each ring, the depth of the frame, as well as the inside radius of the sphere. I'm really enjoying exploring the potentials of the grasshopper plugin, I'm finding it to be pretty intuitive and easy to learn once you get the logic that it operates around. The last image is the grasshopper interface which I guess operates much like a circuit board.

Subscribe to:

Posts (Atom)